“Quality first, customer first, Continuous improvement to exceeds customer's requirements and expectations.“

Our Quality Control Department is the cornerstone of our business. We strictly implement all aspects of customer requirements in terms of specications and industry guidelines.

Our mold development has adopted key tools from the automotive industry. All new mold avoid potential risks through failure mode and effects analysis(FMEA).

Our simultaneous remote video inspection allows customers and JKP to view products, tool trial, tool disassemble etc. in real time for saving time, manpower and management.

ISO 14001: 2016 IAF/CNAS certied.

ISO 9001: 201 2016 IAF/CNAS certied.

1.Mold DFM, Moldflow, Design Control

2.Mold Steel Incoming Size, Hardness Inspection

3.Mold Core And Cavity Milling Inspection

4.Mold Electrodes Inspection

5.Mold Pre-Assemble Inspection

6.Mold Trial And Sample Inspection

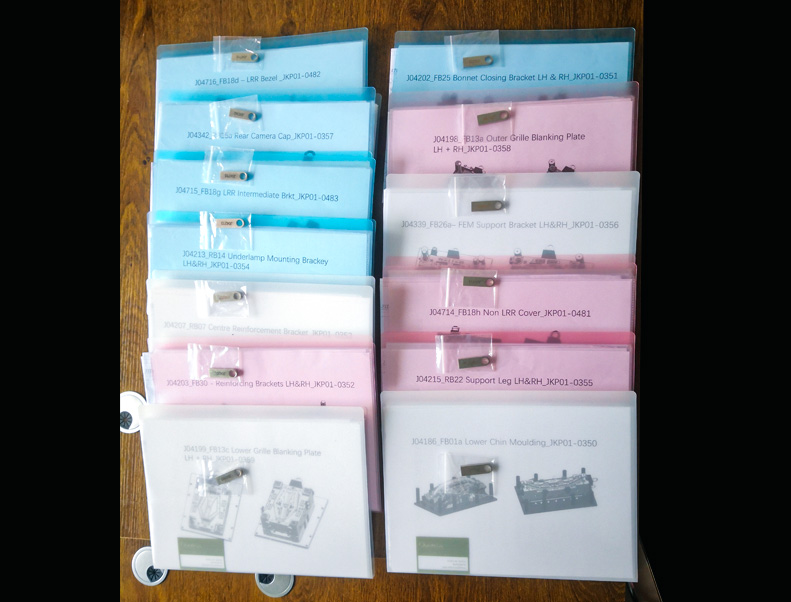

7.Sample Package and Delivery Inspection

8.Mold Pre-Shipment Disassemble Inspection

9.Mold Package and Delivery Inspection

10.Mold Shipment Documents Inspection

Electrodes CMM Inspection

Steel CMM Inspection

Mold Package

Mold shipment document